[ad_1]

Cable trays are an essential part of modern industrial infrastructure and civil construction. With the rapid development of electrification and information technology, its importance cannot be overstated. However, supporting and maintaining cable trays is often difficult and can lead to significant economic and social losses in the event of an accident, so ensuring safety and reliability is paramount. is.

The last few decades have seen significant developments in the field of cable trays. Researchers investigated various aspects of cable tray design and performance, considering service requirements such as:

- earthquake resistance,

- Corrosion resistance,

- flame retardant performance and

- Immunity to electromagnetic interference.

This is especially true for cable-stayed bridge and rooftop designs with large numbers of cables. These studies led to the development of safer and more efficient cable tray systems.

In addition to traditional requirements, new demands are also emerging, such as the need for cable trays with larger spans, reduced weight, and simpler construction, reflecting resource conservation and environmental concerns.

In this article, we take a closer look at how cable tray support solutions can improve rooftop and facility safety and help improve compliance and reliability. We will also highlight some important considerations that professionals should make regarding these rooftop support systems.

Important factors in choosing a cable tray support

There are three main factors to consider when installing a cable tray support solution:

- Earthquake resistance/corrosion resistance: To ensure long-term safety and reliability, cable trays must withstand seismic forces and be corrosion resistant. Any failure can lead to significant economic and social losses.

- Large span, lightweight, easy construction: As new demands for cable trays emerge, such as large spans, lightweight materials, and ease of construction, engineers must adapt their designs to meet these requirements while maintaining safety and reliability. .

- stress and deformation: The ability to withstand both stress and deformation is very important in cable tray design. Cable trays, whether used for power transmission or control equipment, must maintain structural integrity while resisting deformation.

All these factors can be attributed primarily to the strength to stiffness ratio. This ratio quantitatively defines the relationship between static load strength compared to cable tray stiffness.

Cable tray strength-stiffness ratio

The strength of a cable tray refers to its ability to withstand loads without damage, and its stiffness refers to its ability to resist deformation. Both strength and stiffness are important factors for cable tray performance. By analyzing this ratio, you can optimize your cable tray design to achieve a more economical and sustainable solution.

Achieving the ideal strength-to-stiffness ratio is important to ensure optimal cable tray performance while maintaining safety. This ratio is expressed as a value close to 1, ensuring that both strength and stiffness conditions are met simultaneously, maximizing material utilization and economic benefit. Achieving the right balance of strength and stiffness is important, and the strength-to-stiffness ratio helps optimize this balance.

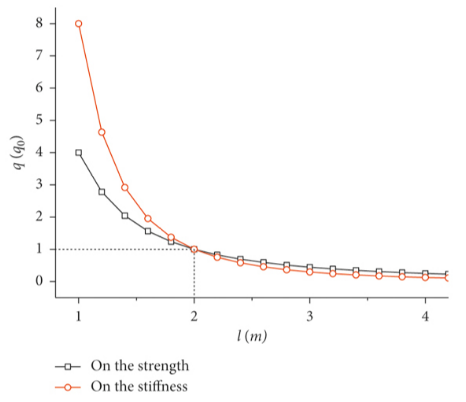

Figure: An example of a relationship graph between strength and stiffness.

The graph above shows the relationship between the strength and stiffness ratio of a cable tray and its load characteristic curve. It shows how this ratio affects performance under different span conditions.

When the strength-stiffness ratio is greater than 1 (where the dimensionless span is less than 1), there are large differences between the load characteristic curves. Here it is recommended to perform a test that combines deflection measurement and load control. This means that the cable tray is stiff and load control is the preferred test method.

If the ratio is less than 1 (dimensionless span greater than 1), the strength-based load characteristic curve lies above the stiffness-based curve. In these cases, it is recommended to perform load tests using deflection control, as the stiffness of the cable tray is less dominant. This approach ensures a relatively safe working load.

For dimensionless spans greater than 1 and less than 1, the difference between the two curves is minimal. This is considered acceptable in engineering and indicates that a strength-to-stiffness ratio close to 1 is reasonable. However, if there are significant differences between the designed span and actual site conditions, the cable tray support system may need to be redesigned to ensure safety and performance.

PHP Systems/Design leverages the concept of strength to stiffness ratio to design cable tray solutions that prioritize durability and long-term performance. We carefully balance strength and stiffness in our cable tray designs. This allows our solutions to withstand the demands of real-world applications.

This approach allows us to provide cable tray solutions that provide both structural integrity and flexibility. This is important to accommodate varying span distances and loading conditions. We guarantee a strength to stiffness ratio close to 1. This means our cable trays are suitable for handling a variety of spans and load scenarios. Additionally, it improves OSHA compliance.

Applying strength and stiffness ratios

The strength-to-stiffness ratio has practical implications both during the design and testing stages of cable trays.

During the design stage:

- When the ratio of strength and stiffness is greater than 1indicating that stiffness is relatively high compared to strength. In such cases, the cable tray can be designed to meet the strength requirements and the stiffness requirements will be met automatically. This ensures that the cable tray operates in ideal operating conditions, leading to efficient material utilization.

- When the ratio of strength and stiffness is less than 1This means that strength requirements take precedence over stiffness. Here, the cable tray must also meet the stiffness condition in order to meet the strength condition. In these cases, cable trays may be designed to maximize strength, taking full advantage of the material’s potential strength.

During the testing phase:

Strength and stiffness ratio also plays an important role in cable tray testing. If the ratio is greater than 1, tests can be performed that focus on load control and deflection measurement. If the ratio is less than 1, the test is suitable for deflection control and may include gradual loading and unloading. These tests help determine safe working loads for cable trays under various conditions.

Determination of strength and stiffness ratio

The strength to stiffness ratio can be determined using numerical analysis, finite element methods, or experimental testing. By comparing the maximum dimensionless deflection and maximum stress values obtained from numerical simulations or physical tests, the strength-to-stiffness ratio can be evaluated. The results of these analyzes or tests can be used as a reference for optimizing cable tray design.

Different materials and strength and stiffness ratios

The material that a cable tray is made of has a significant impact on its strength and stiffness ratio. Different materials have different values of allowable strain and conditional yield strain. For example, cable trays made of engineering plastics typically have lower strength but higher conditional yield strain values than metal-based trays.

Therefore, the materials used must be carefully considered when designing and evaluating cable trays, as they can affect the cable tray’s strength-to-stiffness ratio and, therefore, its performance. PHP uses a mixture of galvanized steel, stainless steel, and aluminum for its cable trays. The idea is to reduce the risk of corrosion and at the same time ensure the durability of the tray.

Load test and strength-stiffness ratio

The influence of strength to stiffness ratio also extends to cable tray load testing. These tests are often performed over a range of spans to establish a load-span curve, or load characteristic curve. The results of these tests help manufacturers understand how their products perform under different conditions.

The strength to stiffness ratio affects load testing, especially when cable trays have different spans. For parts with dimensionless spans less than 1 and strength-to-stiffness ratios greater than 1, use load control to evaluate cable tray performance. In contrast, when the dimensionless span is greater than 1 and the strength-to-stiffness ratio is less than 1, deflection control is better.

How PHP systems/design can help

At PHP Systems/Design, we specialize in creating customized cable tray support solutions that take into account the strength to stiffness ratio and several other important factors. These include, but are not limited to:

- allowable strain,

- Allowable dimensionless deflection,

- height span ratio, and

- Characteristic coefficient.

Our aim is to ensure that cable tray systems operate under ideal conditions, where safety is never compromised and material usage is optimized. Whether your project requires cable trays for power transmission or control equipment, our team of experts can provide a solution tailored to your unique needs.

Request test data for your facility

To better understand how different materials and designs can benefit your assets, PHP Systems/Design recommends requesting test data from experts. That way, you can make informed decisions about your cable tray support system based on real data. If you’re ready to get started, you can also request pricing and start your project right away.

[ad_2]

Source link